|

| |

| Sponsored by Westpak Inc. |

| |

|

| |

| SPONSOR MESSAGE |

| |

|

Webinar: Medical Device Package Failures

WESTPAK presents a novel testing topic: "Case Studies of Medical Device Package Failures." Subject matter expert, Ms. Katie Tran, |

|

| Principal Quality Systems Engineer, reviews failures revealed during sterile barrier package system testing and offers proven solutions to improve quality, reduce pain, and deliver success. |

| |

| Register now » |

| |

|

|

| |

| |

| |

|

| Reliability Testing: Thermal Stress |

| WESTPAK's thermal testing capability includes thermal shock, thermal cycling, and exposure over a specified temperature range. Testing can also include varying humidity or simulated altitude levels. Temperature cycling ramp rates of +/- 5°C per minute are achievable. Overall product reliability can be improved by addressing vulnerable material and product elements identified by testing. |

| |

| Learn more » |

|

|

| |

| |

| |

| |

|

| |

SPONSOR MESSAGE |

| |

|

|

| Medical Device Package Validation |

| Package validation for medical device and pharmaceutical packaging are two primary test areas. For the medical device packaging where a sterile barrier is required, testing is performed under the guidance of ISO 11607. Pharmaceutical cold-chain shipments require a temperature-controlled package system and occasionally real-time temperature reporting. |

| |

| Learn more » |

| |

|

|

| |

| |

| |

|

| Why Is Ice So Slippery? |

| Though millions have been spent to understand ice at the molecular level, one question remains: Why is ice so slippery? One scientific team used advanced optical microscopes to observe what the X-rays of the '80s detected: a nanometer-level, super-thin coating of water always sitting on top of the ice. |

| |

| Learn more » |

|

|

| |

| |

| |

| |

|

| |

SPONSOR MESSAGE |

| |

|

|

| Arrhenius Demystified: Accelerated Aging |

| WESTPAK's Arrhenius Equation Demystified webinar presents the background and basis for Accelerated Aging when using an elevated temperature to evaluate medical device package systems. However, the underlying principles and equation can be applied to evaluate materials from many other industries to determine the adverse effects of time in less time. |

| |

| Download slide deck » |

| |

|

|

| |

| |

| |

|

| Integrity Is the Priceless Ingredient |

| Integrity is paramount in the testing business, and especially with data integrity. WESTPAK teaches "no data is better than bad data" solely because a decision based on bad data will be the wrong decision every time. Charged with approving life-critical pharmaceuticals and products based on test data, the FDA offers guidance on this and related topics. |

| |

| Download the FDA presentation » |

|

|

| |

| |

| |

| |

|

| |

SPONSOR MESSAGE |

| |

|

|

| Why Shipping Tests Don't Work |

| Does your firm use shipping tests or "trial shipments" as part of its package system validation process? While one such shipment would be statistically insignificant and lead to wrong conclusions, conducting dozens as a trial might be impractical and costly. Here's why testing in a controlled, repeatable, laboratory environment is recommended. |

| |

| Download white paper » |

| |

|

|

| |

| |

| |

|

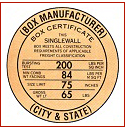

| Material Analysis: Mullen Burst Testing |

| Mullen burst testing determines the bursting strength of single-wall and double-wall corrugated board per the TAPPI T-810 test method. The minimum bursting strength of corrugated board is a requirement of transport shipping regulations worldwide. Test specimens are conditioned in environmental chambers before testing. |

| |

| Learn more » |

|

|

| |

| |

| |